Fire safe & energy efficient: facade subframe system ALWI with aluminum L-shaped Flex wall brackets

Innovations

Information

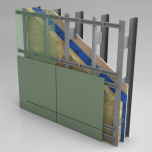

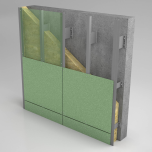

The subframe system ALWI with aluminum L-shaped Flex wall brackets is made from high quality aluminum for visible or concealed fastening of large-format cladding panels, e.g. made of fiber cement (FCB), aluminum composite material (ACM) or high pressure laminate (HPL). In conjunction with an additional rail system also suitable for fastening of terracotta/clay tiles.

The ALWI subframe system can be used for stud walls as well as for masonry and enables perpendicular alignment for highest facade aesthetics.

The non-combustible aluminum wall brackets made using alloy EN AW-6063 T66 have an optimal thermal conductivity and meet the highest fire safety demands. The special Flex back-hole pattern allows highest cost efficiency thanks to only one

bracket version for all common substrates. The brackets are available in lengths from 40 mm to 320 mm and are used for fixing onto concrete /masonry and wooden/metal frameworks.

All SYSTEA systems meet ASHRAE 90.1 standards and help achieve minimum requirements for energy efficient buildings. Several components are Passive House Certified and eligible to LEED, BREEAM, Green globe or other high sustainability requirement project. Also, as fire safety is a critical topic in designing buildings, the ALWI systems are non-combustible for a worry free specification.

Main systems advantages at a glance:

- Highly cost efficient system

- Non-combustible material

- Most sophisticated facade designs possible

- Meet the highest static requirements

- Dimensional accuracy of all components

- Corrosion resistant and particularly durable

- Fixed and sliding points provide secure hold

- Sturdy lightweight high quality aluminum

Product Category

Framework: Building envelope

Launch date

4/28/2021